Crossbow Organizational Model: A Smarter Approach for MSME Manufacturing

The Crossbow Organizational Network is a structured framework designed to improve communication, compliance, and operational efficiency in MSME manufacturing units. It establishes clear roles and responsibilities for each department while ensuring that interactions are purpose-driven and data-driven rather than arbitrary.

Organizational development is a necessity for MSMEs to scale and growth in their industry while doing real business rather than managing day to day chaos. Irrespective of the industries across MSMEs in india it is prevalent that organizations are struggling to organize quickly as per the external environment and are further challenged in growing their capabilities fast as per industrial benchmarking.

MSMEs in manufacturing frequently encounter operational bottlenecks, mismanaged inventories, inefficient communication, and production delays. These issues arise due to poorly structured interdepartmental interactions and lack of process standardization.

This approach ensures that sales, production, and inventory teams collaborate effectively, but only where necessary, minimizing redundant communication, improving compliance, and maintaining product quality consistency.

Understanding the Crossbow Organizational Network

The network is structured around three key departments:

- Sales & Customer Service – Responsible for order acquisition, customer inquiries, and demand forecasting.

- Stocks & Logistics – Manages raw material inventory, finished goods availability, and order fulfillment.

- Production Unit – Focuses on manufacturing products, maintaining quality, and ensuring operational efficiency.

At the center of this framework is the Center Decision Hub, which functions as a gatekeeper for approvals and compliance management to ensure all operations align with business objectives.

A Crossbow Organizational Network for decision-making in an MSME manufacturing unit ensures efficient coordination between Inventory Management, Logistics & Supply Chain, Sales, and Production departments. This model integrates structured communication, accountability, and quick responsiveness.

Crossbow Organizational Network – For MSME Manufacturing Unit

(Decision-making flow and collaboration structure)

1. Core Elements of the Crossbow Model

- Central Decision Hub (CDH): Led by the Operations Head or MSME Owner, where key decisions are made based on input from various teams.

- Inventory Management, Sales, and Production Teams act as interconnected arms, providing real-time updates and taking actions based on decisions.

- Digital Integration: Use of ERP or MIS for data transparency.

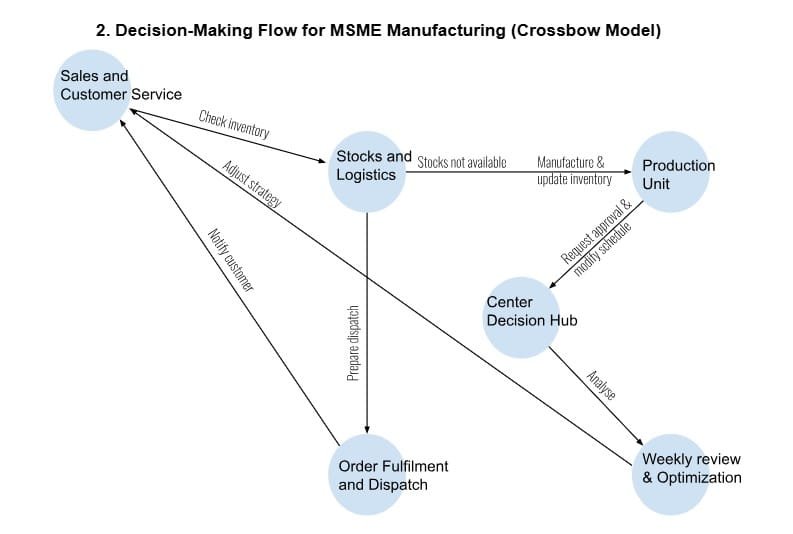

Here’s a structured decision-making flow for the Crossbow Organizational Network in MSME manufacturing:

Step 1: Order Acquisition

Sales & Customer Service receives an order from a customer.

Sales team logs order details in the system and communicates with Stocks & Logistics to check inventory availability.

Step 2: Inventory Verification

Stocks & Logistics checks if the required product is available in inventory:

- If Available: Sales proceeds with order fulfillment, and logistics prepares for dispatch.

- If Not Available: Stocks & Logistics assesses raw material and production requirements.

Step 3: Production Decision

Stocks & Logistics communicates with Production Unit to determine feasibility:

- If Production Capacity Exists: Stocks & Logistics submits a production request to the Center Decision Hub.

- If Capacity is Limited: Decision hub prioritizes orders and adjusts production schedules accordingly.

Step 4: Approval from Center Decision Hub

Center Decision Hub Reviews:

- Checks inventory levels, material availability, and production capacity.

- Approves or modifies production schedules based on demand patterns.

- Ensures compliance with the MSME’s standard production policies.

Step 5: Production Execution

- Production Unit begins manufacturing based on approved schedules.

- Stocks & Logistics updates Sales on expected completion timelines.

Step 6: Order Fulfillment & Dispatch

- Once production is completed, finished goods are handed over to Logistics.

- Logistics dispatches the order to the customer and updates the sales team.

Step 7: Weekly Review & Process Optimization

Center Decision Hub conducts weekly reviews with:

- Sales (demand trends)

- Stocks & Logistics (inventory turnover)

- Production (efficiency and delays)

Identifies areas of improvement and updates operational strategies.

Key Restrictions to Ensure Smooth Operations:

- Sales must not communicate directly with Production.

- Production does not receive direct customer orders.

- Only the Center Decision Hub can authorize production changes.

This structured flow reduces confusion, improves lead times, optimizes inventory, and ensures consistent product quality.

3. Communication & Technology Integration

- Real-Time Dashboards: Shared across Sales, Production, and Inventory Management for transparency.

- Automated Alerts: ERP-based alerts for low stock, delayed dispatch, or urgent sales orders.

- Cross-Functional Meetings:

- Daily Stand-ups: Quick updates within teams.

- Weekly Sync: CDH reviews cross-functional updates.

- Monthly Strategy Review: Leadership alignment on trends and improvements.

4. Roles & Responsibilities in the Network

| Department | Key Responsibilities | Decision Authority |

| Sales | Customer orders, demand forecasting, competitor analysis | Priority order requests, service adjustments |

| Production | Manufacturing planning, resource allocation, quality checks | Work shifts, production priority changes |

| Inventory Management | Inventory tracking, dispatch scheduling, warehouse management | Stock procurement, logistics coordination |

| CDH (Owner/Head) | Strategy alignment, final approvals, issue resolution | Major resource shifts, policy decisions |

Communication Patterns in the Crossbow Organizational Network

The key principle behind this model is structured, role-based communication to prevent unnecessary disruptions and inefficiencies.

1. Direct Communication Channels:

- Sales ↔ Stocks & Logistics: Sales teams inform inventory teams about new orders and expected demand.

- Stocks & Logistics ↔ Production: Inventory teams communicate material availability and replenishment status to production.

2. Restricted Communication Channels:

- Between Sales Production: Sales teams do NOT communicate directly with production to ensure product quality remains standardized.

- Between Production Sales: Production does NOT take direct instructions from sales to prevent custom orders from disrupting manufacturing efficiency.

Why Sales and Production Must Not Interact Directly:

- Standardization of Products: Direct sales-to-production communication can lead to unapproved customizations, making production inconsistent.

- Prevention of Production Overload: Without a structured approach, sales might push urgent orders directly to production, leading to operational chaos.

- Inventory-Based Production Planning: Sales must coordinate through inventory management, ensuring that production operates within stock constraints.

Role of the Center Decision Hub

The Center Decision Hub functions as the control unit that ensures process compliance and structured workflows. It acts as an approval authority and a system development entity, focusing on long-term efficiency rather than day-to-day operational micromanagement.

Core Responsibilities of the Center Decision Hub:

Approval & Compliance Management:

- Reviews production schedules and inventory levels before approving new manufacturing orders.

- Ensures sales orders align with stock availability before processing.

Strategic Review and System Development:

- Holds weekly review meetings to analyze inventory turnover, production efficiency, and sales trends.

- Identifies bottlenecks in communication and process flow, implementing system improvements where necessary.

Process Enforcement:

- Ensures sales and production follow the structured communication flow without bypassing inventory management.

- Monitors adherence to the make-to-order or stock-based production approach.

Limitations of the Center Decision Hub in Daily Operations

While the Center Decision Hub plays a crucial role in compliance and system oversight, it is not designed for real-time operational interventions.

Key Limitations:

Does Not Manage Routine Logistics:

- It does not interfere in day-to-day material movement unless there is a compliance issue.

Does Not Resolve On-Ground Production Issues:

- If a machine breaks down or a worker shortage occurs, production teams must handle it internally rather than seeking immediate intervention from the decision hub.

Does Not Replace Departmental Responsibilities:

- Each department remains accountable for its operations – the decision hub only ensures alignment between them.

Process Compliance and Implementation in MSMEs

Steps to Implement the Crossbow Organizational Network in an MSME:

Data Management System:

- Use real-time inventory tracking tools to keep sales and production teams updated on stock availability.

Direct Communication Channels:

- Implement a structured order processing system where sales updates inventory, and inventory notifies production.

Approval Checkpoints:

- Introduce approval stages where large orders or production schedule changes require Center Decision Hub authorization.

Standardized Review Meetings:

- Conduct weekly strategic review sessions to improve workflows and eliminate inefficiencies.

Departmental Role Clarity:

- Clearly define that sales will NOT communicate directly with production to maintain workflow discipline.

How MSMEs Benefit from This Model

- Reduced Inventory Turnover – Aligns stock levels with real-time demand.

- More Efficient Production Planning – Ensures production runs smoothly without ad-hoc orders disrupting schedules.

- Lower Lead Times – Streamlined workflows result in faster order fulfillment.

- Improved Customer Satisfaction – Timely deliveries due to better coordination between sales and logistics.

By structuring departmental interactions, approvals, and data-driven decision-making, MSMEs can scale their manufacturing operations without inefficiencies or misalignment.